In Part 2 we saw the Parmesan covered and sitting to allow the Reggiano brand to imprint and for the cheese to reach the desired stage of firmness, so it can then proceed to the next stage in the cheese making process.

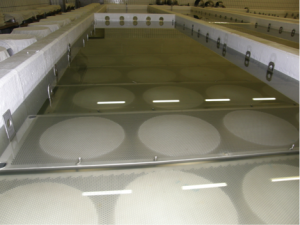

Once the rounds are set they are transferred into a salt-water bath. The salt and water mixture and the water temperature are very tightly controlled. It should be noted, that up to this point nothing has be added to the milk, so the two main ingredients in Reggiano are milk and the salt that is absorbed in the bathing process. How simple is that and yet what a flavourful cheese!

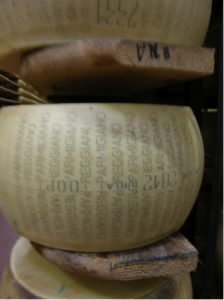

After the bathing process is complete the rounds are placed on wooden planks to age. The aging process can be up to 30 months for the oldest and most flavourful of the Parmesans. Next time in the shop ask me how long the Parmesan I carry has bee aged! Notice how light the printing is and how white the cheese round is. This will change significantly during the aging of the cheese.

The rounds do not just sit idley on the planks, they have to turned constantly so that the aging and density of the cheese is consistant throughout. Watch this video closely and you will see that two rounds at a time are being turned. Keep in mind that the process you are watching used to be all done by hand, without the aid of technology! Not an easy task!

Next month in Marking Parmesan Part 4 we will see what happens as we get closer yet to the final product that ends up on your table!